Renovating my Workshop

A fresh new setup after 15 years…

Now that I will spend more time in my work shop, it was about time to get things fresh and renewed. After many (15) years of organic and chaotic growth I wanted to get things more organized and all test equipment and work space more handy. Well there is not so much to say about this, so I will let the pictures speak mostly for itself:

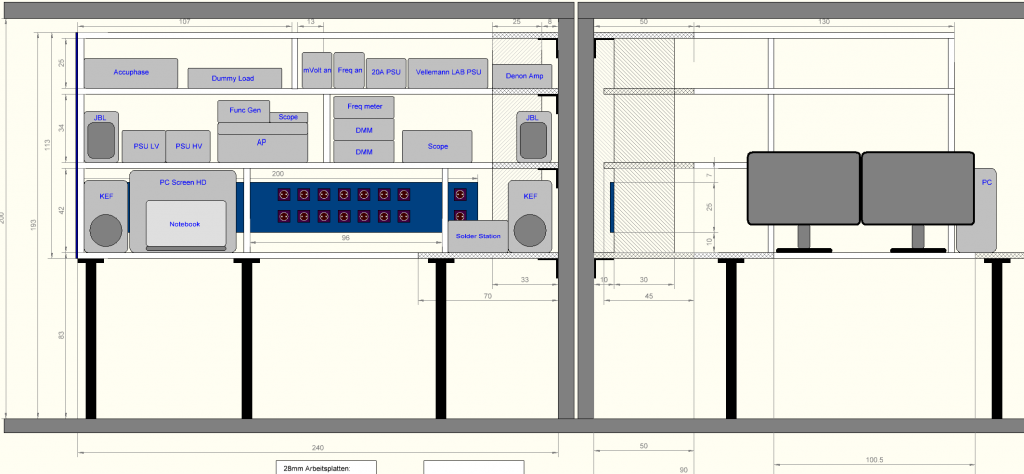

As an experienced user of Abacom sPlan, I am used to draw everything with this CAD program. Regardless if it is electronics or stuff around the house. I like the function where you can drag and draw the arrows with the dimensions. Which helps ordering the shelfs.

I took the time to measure up all my equipment and drawing small function blocks which I could move a round till I liked it. Just buying a standard rack or shelf system always is like, “shit, these two pieces of equipment will just NOT fit in here” Hence wasting space or not being able to set it up to my likings.

I found a nice online shop here in Germany who can deliver shelfs to a mm precision and with high quality material and finish. Not cheap, but hey, you get something and you will use this for the next, what, 10 20 years? The company is called Expresszuschnitt ; have a look for your self. There are other similar companies of course – this is not paid influencer BS, LOL

Preparation ongoing. Shelfs being delivered, cleaning out the old work shop, storing everything in the listening room and getting ready. At one point you really think “how on earth did I let it even come to this?” ….

During the years, I added so much equipment I had a total mess of many many table sockets. Which is not only an ugly view, but to be honest also a hazard danger (!!). So as I was able to do some decent planning this time, I decided to make ENOUGH mains sockets…. May be overkill, but hey, better safe than sorry!

Thanks to the exact dimensions and precise production of the shelfs and other panels, the work bench built up like an IKEA puzzle 😉 Putting all the equipment in place really sparked joy.

One last thing: with doing functioning and repair testing, I always used the amplifiers, DAC and test speakers which were in the rack. Imagine the cable management? Just lying around somewhere till you need to connect something. I decide to use an old 19″-rack front panel to create a “Connection Hub” Now I have all connections for inputs and outputs of audio signals directly at in front of me and ready for a stable connection…

Summary

Well, big word summary…. Lets sum it up, I really enjoy being in this room and it is a joy to do test and development work here now. I am very happy I took the time and I hope it might be a stimulus for other people to do something similar 🙂

Next time I will blog on the new available DDDAC MC Pre Pre amplifier board 🙂

3 thoughts on “Renovating my Workshop”

De Weller soldeerbout helemaal op de bovenste plank dat mag natuurlijk niet in zo’n mooie werkplaats.

LOL, dat is de reserve bout 🙂 Het station met de desoldeermogelijkheid staat duidelijk beter en wordt bijna dagelijks gebruikt !

Very nice shop/lab. Looks great and appears very functional.